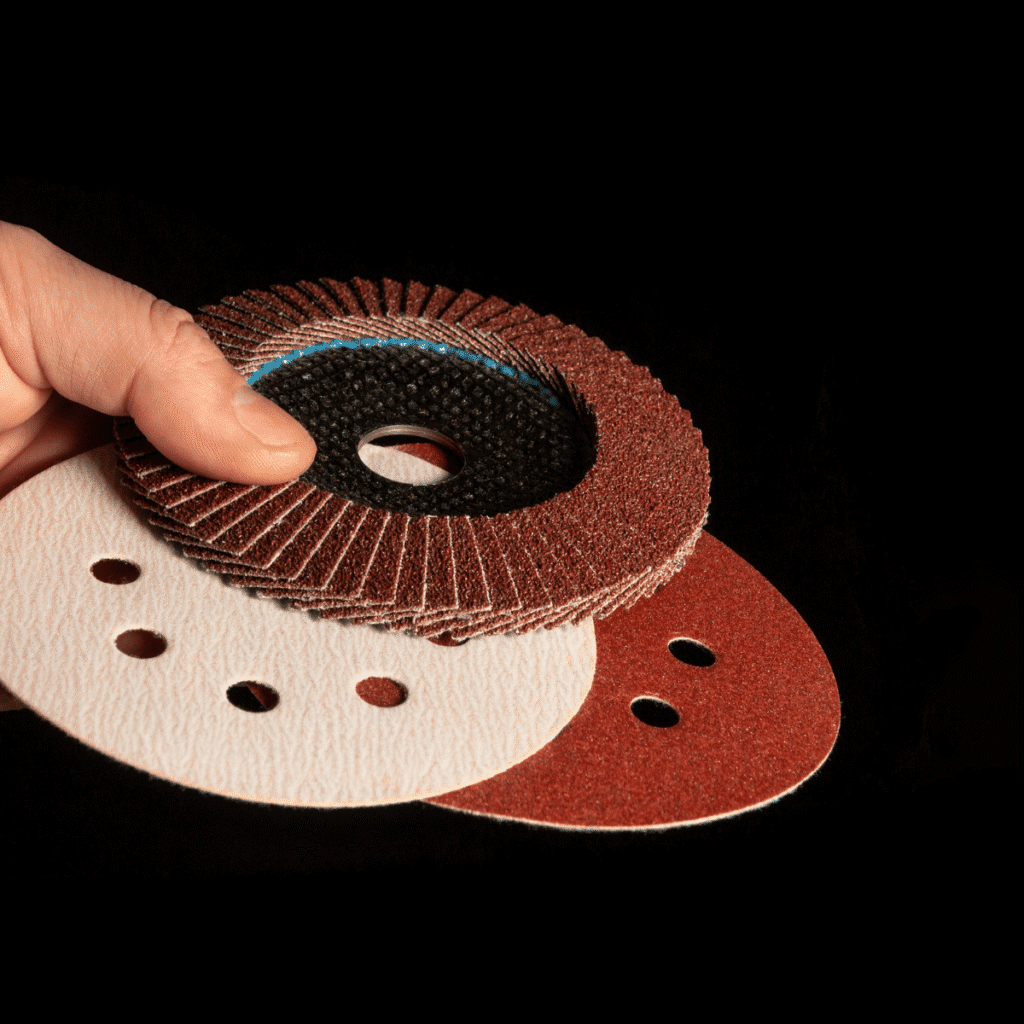

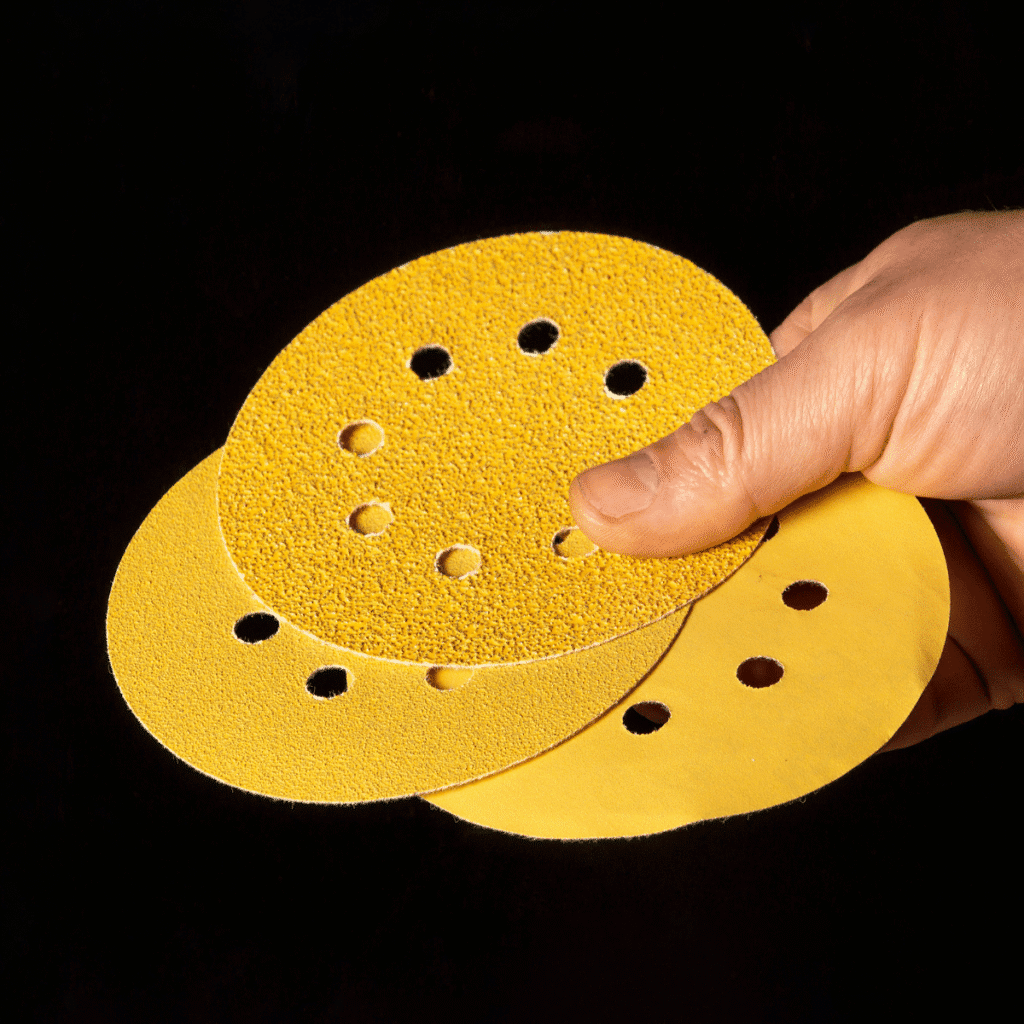

Velcro Sanding Discs for Painting Industry Applications

Table of Contents

When it comes to painting and refinishing, surface preparation is the foundation of a perfect finish. After primer application and metal putty work, sanding ensures smoothness, adhesion, and long-lasting results. That’s why professionals in the painting, automotive, and metal finishing industries rely on Velcro sanding discs for painting.

What Makes Velcro Sanding Discs Ideal for Painting?

Velcro sanding discs (also called hook & loop sanding discs) are designed for easy attachment to orbital sanders. They save time with quick disc changes and deliver a uniform finish—critical in painting applications where surface quality defines the outcome.

Key Applications in Painting Process

- After Metal Putty / Body Filler

- Levels uneven surfaces and repairs

- Creates a flat, defect-free base

- Prepares for primer application

- After Primer Application

- Smoothens primer coats

- Removes dust nibs, scratches, and runs

- Ensures better topcoat adhesion

- Pre-Paint Surface Preparation

- Fine sanding before applying topcoat

- Prevents paint defects like orange peel or poor bonding

Best Types of Velcro Sanding Discs for Painters

- Aluminum Oxide Discs – affordable, multipurpose, ideal for primer sanding

- Silicon Carbide Discs – sharp cutting ability, perfect for fine finishing

- Ceramic Discs – heavy-duty and long-lasting, used for tough materials

Recommended Grits for Painting Applications

- 80–120 Grit – shaping and leveling body filler / metal putty

- 150–240 Grit – sanding primer coats

- 320–600 Grit – fine finishing before painting

Why Quality Matters in Sanding Discs

Low-quality discs may clog, wear out quickly, or leave scratches that show through the paint. A premium Velcro sanding disc should offer:

- Strong hook & loop backing for firm grip

- Even abrasive coating for consistent sanding

- Resistance to clogging with primers & fillers

- Long life for cost efficiency

- Compatibility with dust extraction systems

Benefits for Painting Industry Professionals

- Faster sanding with reduced effort

- Smooth, uniform surfaces for flawless paint finish

- Less rework and wastage

- Cost savings over time

Frequently Asked Questions (FAQ)

Q1. What grit sanding disc should I use after applying primer?

For primer sanding, 150–240 grit Velcro discs are ideal. They remove surface imperfections and prepare the surface for topcoat adhesion.

Q2. Which sanding disc is best for metal putty or body filler?

Use 80–120 grit discs to level and smooth body filler or putty before primer application.

Q3. Can Velcro sanding discs be used for both wet and dry sanding?

Yes, many silicon carbide Velcro discs are suitable for wet or dry applications, especially in automotive refinishing.

Q4. How long does a Velcro sanding disc last?

Disc life depends on the abrasive type, grit size, and application. Ceramic discs offer the longest lifespan, while aluminum oxide is more economical but wears faster.

Q5. Why should I choose premium discs instead of cheaper alternatives?

Premium discs provide better cut, longer life, less clogging, and a superior finish, reducing rework and saving costs over time.

Q6. Do Velcro sanding discs work with all orbital sanders?

Yes, as long as the sander uses a hook & loop pad system, Velcro sanding discs are compatible.

Get the Right Sanding Disc for Painting

If you are in the painting, automotive body shop, or industrial coating industry, choosing the right Velcro sanding disc can make the difference between an average finish and a professional one.

At STANCE PROJECTS, we supply premium Velcro sanding discs tailored for painting industry applications—primer sanding, metal putty finishing, and pre-paint preparation.

👉 Explore our abrasive solutions here

Contact us today to source durable and high-performance Velcro sanding discs at competitive prices.